Expand your wool innovations with warp knitting technology. From flexible structures to three-dimensional garments, warp knitting technology offers opportunity for unique design development.

Warp Knitting Technology

Stable structures

Warp knitting produces fabric with stable structures, which are difficult to unravel

Elasticity

Produces fabric with more elasticity in the length, and less elasticity in the width

Seamless garments

Create flat width tubular or three-dimensional garments

How it works

A fast method of knitting, warp knitting machinery is often used to create long runs of fabric using undyed yarns. The fast production of warp knitting creates fabrics suitable for a wide range of end uses.

With stable structures that are difficult to unravel, flexible open or closed structures, and tubular or three-dimensional seamless garments with generous widths up to 6 metres, warp knitting produces fabrics quickly with low cost-to-performance ratio.

Seamless knitwear with warp knitting machines

On new generation warp machines, seamless knitwear can be produced for greater next-to-skin comfort. Seamless knitwear is knitted in a tube, and despite the name, may require seams during final garment assembly. This type of knitting technology is rapidly developing to compete with complete garment knitting and is popular for creating activewear. Karl Meyer, our key partner in warp knitting technology, specialises in this method of wool product development.

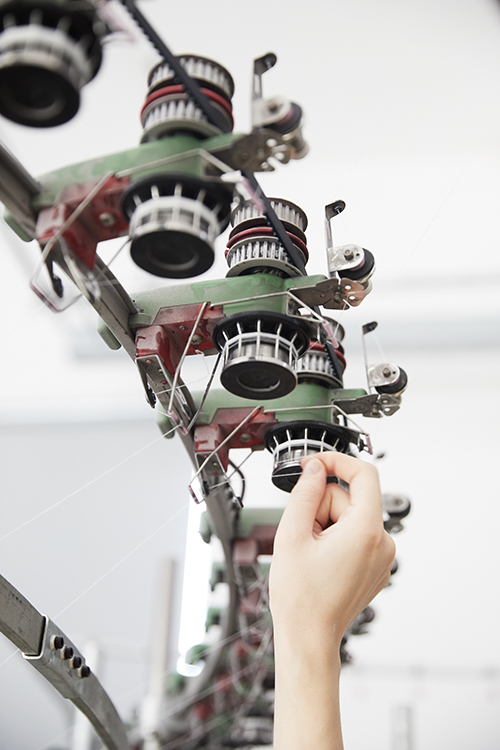

In warp knitting machines, a series of yarn threads (the warp) are threaded through yarn guides, directing the yarn around a needle to create parallel rows of loops (stitches) interlocked in a zig-zag pattern to form fabric.

The needle rises and falls where the previous loop is cleared as the needle rises. The loop is then knocked over as the needle descends with the new loop. To ensure the knockover properly occurs, a ‘presser bar’ closes on a bearded needle to ensure the lower loop moves properly over the outside of the beard. Then, the yarn guides move to another needle and the process repeats.

Warp knitting produces:

- Quickly with low cost-to-performance ratio

- Fabric with stable structures, which are difficult to unravel

- Fabric with more elasticity in the length, and less elasticity in the width

- Flexible structures such as open or closed structures like lace or stitch-bonded fabric

- Seamless garments – flat width tubular or three-dimensional

- Generous widths up to 6 metres, although narrow options are available

Contact us to learn more.

Advanced Knitting Technologies

Develop your knitwear process and boost creativity with the latest advanced technologies to enter the market. With innovative knitwear machinery and emerging spinning processes and yarns, the latest advanced knitting technologies present new potential for knitted wool garments.

Explore the journey of knitted garments through the evolution and use of knitting machinery. With knitwear design ever evolving alongside advances in knitwear technology, harness the dynamic opportunities for wool apparel and accessories innovation. From circular knitting to warp knitting and flat bed knitting to complete garment creation, discover the unlimited creative possibilities of advanced knitting technologies.

Enter the world of advanced knitting technologies and contact our technical team for more information.